Drills buying guide

Find lots of handy information, plus frequently asked questions to help you choose the perfect drill for every job.

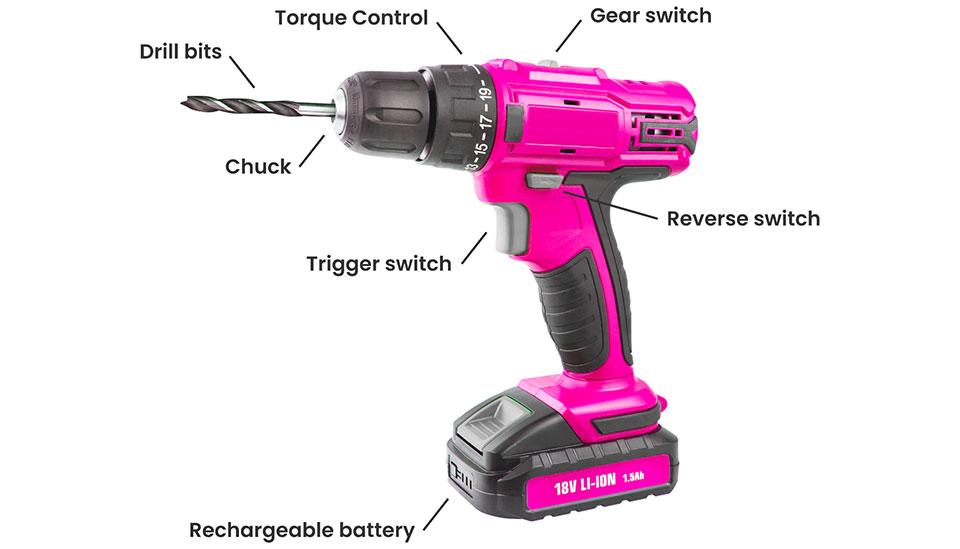

Drill features

Trigger switch: you’ll need to hold this down to operate the drill.

Chuck: this where you insert the drill bit. To tighten or loosen the chuck, hold the handgrip and gently squeeze the trigger switch.

Torque control: use this to adjust the drilling power to suit your job. Look out for a specific setting for drilling holes and remember you will require a less powerful setting for driving screws or you could damage the screw head.

Gear switch: this controls the speed of the drill rotation. Typically, a lower gear will be used for driving light screws and a higher gear for drilling holes and driving bigger screws.

Reverse switch: this changes the direction of the drill between clockwise and anti-clockwise. The switch can also be positioned in the middle to disable rotation completely.

Rechargeable battery: powers cordless drills and will detach for recharging.

Drill bits: these are the various size attachments that fit into the chuck of your drill. They come in lots of sizes and shapes and can create many different types of holes in different materials.

Types of drills

What is a SDS drill?

A cylinder of compressed air enables the drill to beat backwards and forwards as it rotates. These drills are best used for drilling hard to very hard materials such as masonry and concrete as they have additional shock absorbing qualities built in.

What is a combi drill?

Also known as hammer drills or impact drills, these are great all-rounders for completing a range of DIY tasks of varying difficulties. The drills work by pounding the drill bit forward whilst rotating to give great power and control.

Perfect for... easy and hard jobs such as drilling holes or driving screws into wood, metal or masonry

Shop now

What is a drill driver?

Also known as hammer drills or impact drills, these are great all-rounders for completing a range of DIY tasks of varying difficulties. The drills work by pounding the drill bit forward whilst rotating to give great power and control.

Perfect for... straight-forward DIY tasks such as drilling holes and driving screws into wood, metal or masonry

Shop now

What is an impact driver?

An impact driver delivers a rotational twisting force. These drills produce a higher rotational torque, making an impact driver the perfect tool to drive screws at speed, particularly large diameter screws. These drills also tend to be smaller and lighter making them more comfortable to work with for extensive screw-driving tasks such as assembling furniture or creating a decking area in your garden.

What is a hammer drill?

Hammer drills are a more powerful option than drill drivers, as they are capable of drilling through harder materials. They use a powerful hammering action to make light work of drilling holes and driving fasteners. The hammer action supports your drilling with a simultaneous striking action, making drilling much quicker and easier. For hammer work, you’ll need toughened tungsten carbide tipped (TCT) masonry bits.

Perfect for... drilling hard materials with an impact mechanism that generates a powerful hammering motion

Shop now

What drills and bits do I need for the following jobs?

When choosing a drill, think about the types of jobs you will be doing. For heavy duty drilling you’ll need more power but for simple shelving and assembly jobs, a lighter weight drill could be a better option.

How to drill into walls

For drilling into a solid brick, stone or concrete wall you’ll need a masonry drill bit.

You will also need to use a drill with a hammer action to drive the bit into the wall. If you’re drilling into a wall with wood panelling, opt for a spur point bit. These are also known as wood bits. They are designed with a sharp point at the tip to help keep the bit on track as it enters the wood.

How to drill into tiles

Power and precision are essential for this task but the most important element in drilling through a tile is the drill bit itself. Regular or masonry bits won’t be strong enough successfully to penetrate the hard surface of a tile so ceramic tiles should be drilled with a carbide drill bit and glass and porcelain tiles will require a diamond-tipped drill bit.

Always use a slower speed when drilling through ceramic tiles. High speeds will create too much friction too quickly and elevate the drill tip speed. This can also dull the carbide bit.

Never use a hammer drill setting when drilling tiles. This rapid pounding will crack the tile in almost all cases. With a slow and steady pressure on the drill and the use of special spear shaped drill bits designed for tiles, you will be able to create a nice, neat hole. Start by drilling as slowly as possible and increasing speed as you work.

How to drill into concrete

You should generally be able to drill through a concrete wall using a hammer drill; however, it is just as easy to do it with an SDS drill. If using a regular drill to drill though concrete, be sure that it is equipped with a hammer mode and that it is powerful enough to handle the task.

If you are looking to drill concrete, stone or granite, you will need a masonry drill bit. Go for a carbide drill bit and remember to check the size of the wall plug you want to use as well as your chuck type. A hammer drill will usually be fitted with a keyless chuck designed for drill bits with straight shanks while an SDS drill is fitted with an SDS chuck designed for use with grooved shanks.

If you are looking to drill a steel reinforced concrete wall, it’s best to use a carbide-tipped drill bit with 3 or 4 cutting edges.

How to drill into brick

A hammer drill should be able to drill through brick without any difficulty. You should use the drill in hammer mode and ensure you have enough power for the task. It should also be equipped with a variable speed drive. Use a tungsten carbide drill bit and always protect your eyes from flying material with safety goggles. If you are drilling into hollow brick, you can usually drill without hammer mode.

Top Tip: Drilling through brick is a messy job and it’s best to clean up the dust using a vacuum cleaner rather than a brush as brick residue can leave marks.

How to drill into metal

Regular drill bits can’t cut through steel, so you need a heavy-duty, hard drill bit to do the job. There are two types of drill bits you can count on for metalworking projects: titanium and cobalt. As the name suggests, cobalt drill bits are made of cobalt steel. Unlike titanium drill bits, they can be sharpened. Cobalt drill bits are very hard, highly heat-resistant, abrasive, and ideal for drilling through cast iron, stainless steel and titanium.

How to drill into glass

Drilling a hole in a pane of glass or a mirror is easier than you think. The key is to use a carbide bit made specifically for glass and tiles. Because glass is extremely smooth and hard, the bit will want to wander as you start drilling. To give the bit a foothold, tape a small scrap of dense cardboard (like cereal box cardboard) to the glass. Begin at very low rpm to create a dimple in the glass, then remove the cardboard and continue at about 400 rpm.

If you’re drilling on a horizontal surface, you can pour a little oil on the area. Make sure the glass is firmly supported on the backside and place only very light pressure on the drill; press too hard and you’ll crack the glass. The bit creates a clean hole on the side it enters, but usually chips the edges of the hole on the other side.

Note: Always check the glass you want to drill is suitable for drilling as some glass such as tempered glass should not be drilled.

FAQs

Should I get a cordless or corded drill?

Corded drills plug in at the mains and can often provide more power and torque than cordless options.

Corded drills are better for longer or more heavy-duty tasks

Cordless drills are easily portable and have a rechargeable battery. If you have two rechargeable batteries, you can simply swap over when one runs out.

Corded drills are ideal for everyday DIY

Did you know? Power for cordless drills is measured in volts and power for corded drills is measured in watts. The higher the number of volts or watts, the more power a drill has.

Should I get a brushed or brushless drill?

All cordless drills convert electricity into power by using the attracting and repelling actions of magnets to get the shaft spinning.

Brushed motors require small metal brushes to work with the magnets to keep the shaft spinning. Brushless models have an electronic circuit board and a sensor to do the same thing.

Brushless motors have several advantages when it comes to performance, reliability, and durability:

1. More energy-efficient

2. More responsive

3. Capable of packing more power, torque, and speed

4. Easier to maintain

5. Smaller and lighter

6. Longer-lasting

Note: Brushed drills require new brushes after every 50 to 60 hours of use, but brushless models don’t have any brushes that need replacement.

What is a wall plug?

Wall plugs are small plastic plugs that fit into materials that are brittle and are not capable of supporting weight, in order for screws or other supports to be inserted into the material. They are essential when hanging cabinets, shelves or mirrors, in fact anything you want to attach to your walls. A normal screw will not stay in plasterboard or masonry without a wall plug. They expand to securely grip the sides of the hole you have drilled and will help to hold the screw in place without damaging your walls. It’s important to find the correct wall plug for the task.